Elmarco Talks webinar series | Nanospider: Techniques for Peak Performance

Developed in the lab, ready for real life

Patented needle-free Nanospider™ technology

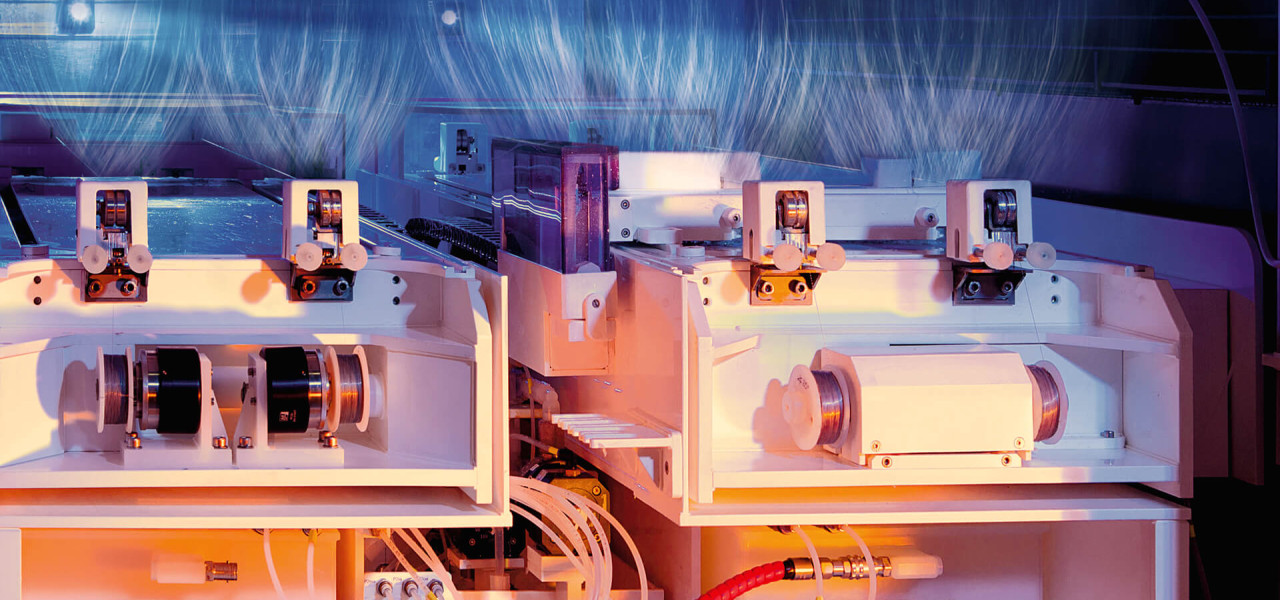

Nanospider™ technology is a unique electrospinning method utilizing the free surface of a polymer solution‑coated electrode in a strong electrostatic field. This technology makes it possible to produce nanofibrous material at the uniformity and throughput suitable for industrial scale manufacturing.

Nanospider™ technology uses an electrospinning electrode in the shape of a thin wire and a head to apply a polymer solution along the entire length of the wire. Nanofibers are then formed from a thin layer of polymer on the electrode under the influence of a strong electrical field.

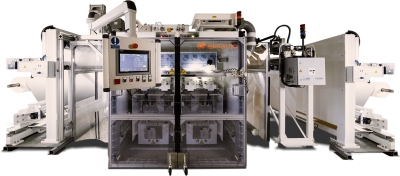

For use in the laboratory and on an industrial scale

Based on Nanospider™ technology, we have developed two product lines for industrial use, which are also complemented by laboratory equipment for nanofiber research and development.

Our technology's invaluable benefits

Important milestones

2003

2004

2006

2007

2008

2010

PRESENTATION OF OWN NEW GENERATION OF NANOSPIDER™ TECHNOLOGY - LINEA LINE

2012

DELIVERY OF PRECISION PROCESS AIR CONDITIONING SYSTEM

2012

2016

2020

2022

INTRODUCING THE NEW INFINITY LINE

Our lines peripherals

Air conditioning unit

- the air conditioner sets ideal conditions inside the electrospinning chamber

- serves for precise control of process humidity and temperature for producing nanofibers

Adhesion module

- this ensures that the layer of nanofibers applied to the substrate will adhere without delamination failures

- used for applying liquid dispersion adhesives to various base materials with smooth and structured surfaces

Hot air dryer

- ensures additional drying of the produced nanomaterial

- layers of nanofibers leave the electrospinning unit with some residual moisture or solvent content, and for this reason the layer must be properly dried before winding

Winding and unwinding

- both the unwinder and winder form steel frames with motors that drive the unwinding and winding pneumatic shafts

- the device enables two-way rewinding of the underlying material.

We provide the equipment through an external supplier.

Polymer Preparation System Compact

- prepares solutions of polymers suitable for electrospinning

- it consists of a mixer, a cabinet with a heating and cooling unit, an accumulation tank and a connection point

- the operation is almost fully automated, except solid polymers must be added manually through a funnel

TEXTEST measuring device

- used for continuous measurement of air permeability, pressure drop, and airflow resistance on moving materials.

- the measurement takes place in real time, and a comprehensive protocol is generated after its completion

We provide the equipment through an external supplier.

Contact us