Cleaner air thanks to nanofibers

Nanofiber filter media are more economical and efficient than conventional filters. They have lower energy requirements and last longer. They can be used in households and industry (HEPA, ULPA), and are suitable for central and mobile air conditioners, humidifiers and cars.

Nanofibers in traditional filter materials

Nanospider™ gives air filter media unique properties

Nanofiber filters improve filtration performance with very little impact on pressure drop, which allows for optimization of the interaction between flow rate, efficiency, and filter lifetime. Nanofiber filters are highly effective at trapping submicron particles, and are fully synthetic and fiberglass free.

Practical use of air filters

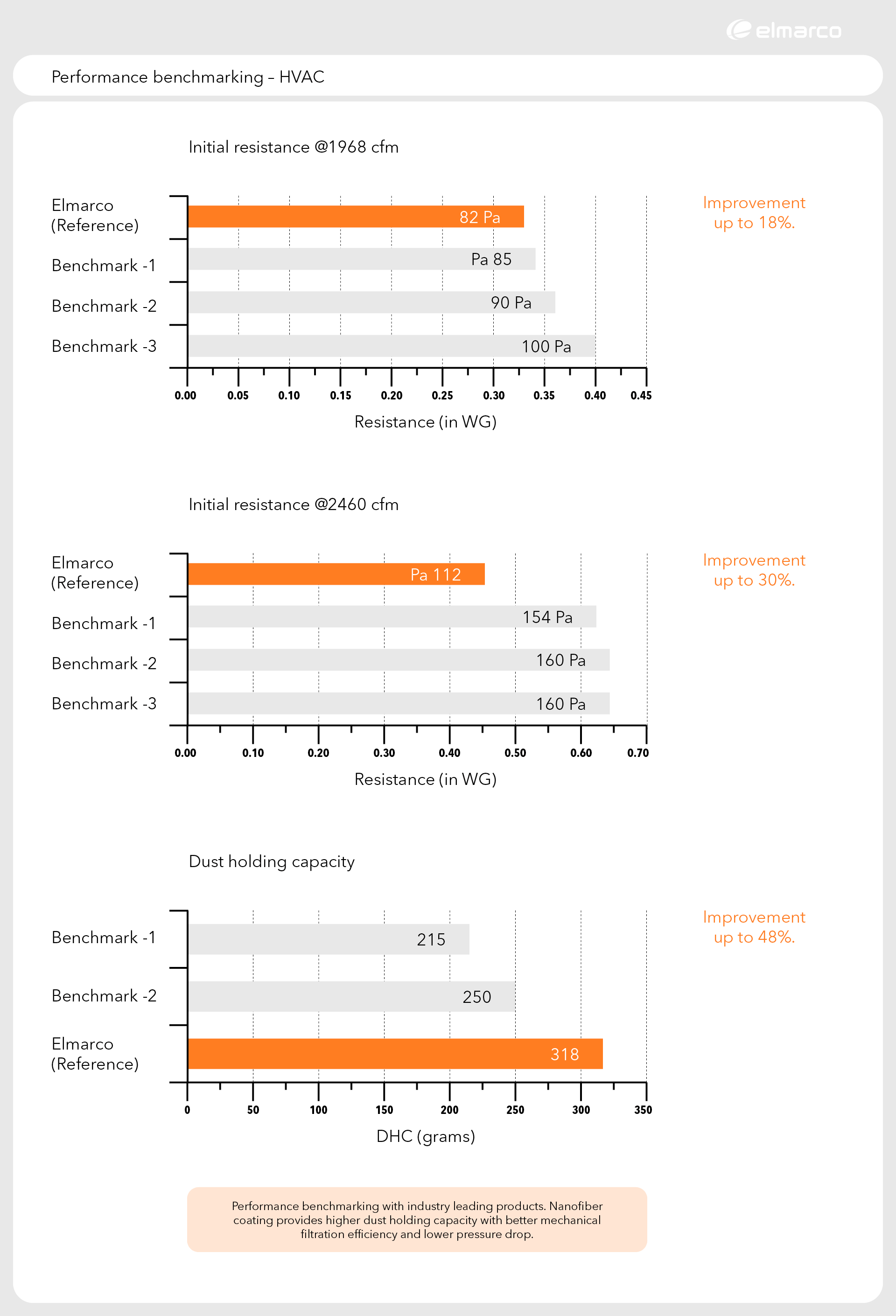

- HVAC air handling filters

Graph: Performance Benchmarking HVAC

Graph: Performance Benchmarking HVAC

- Domestic air filters

- Engine air intake system filters

- Automotive cabin air filters

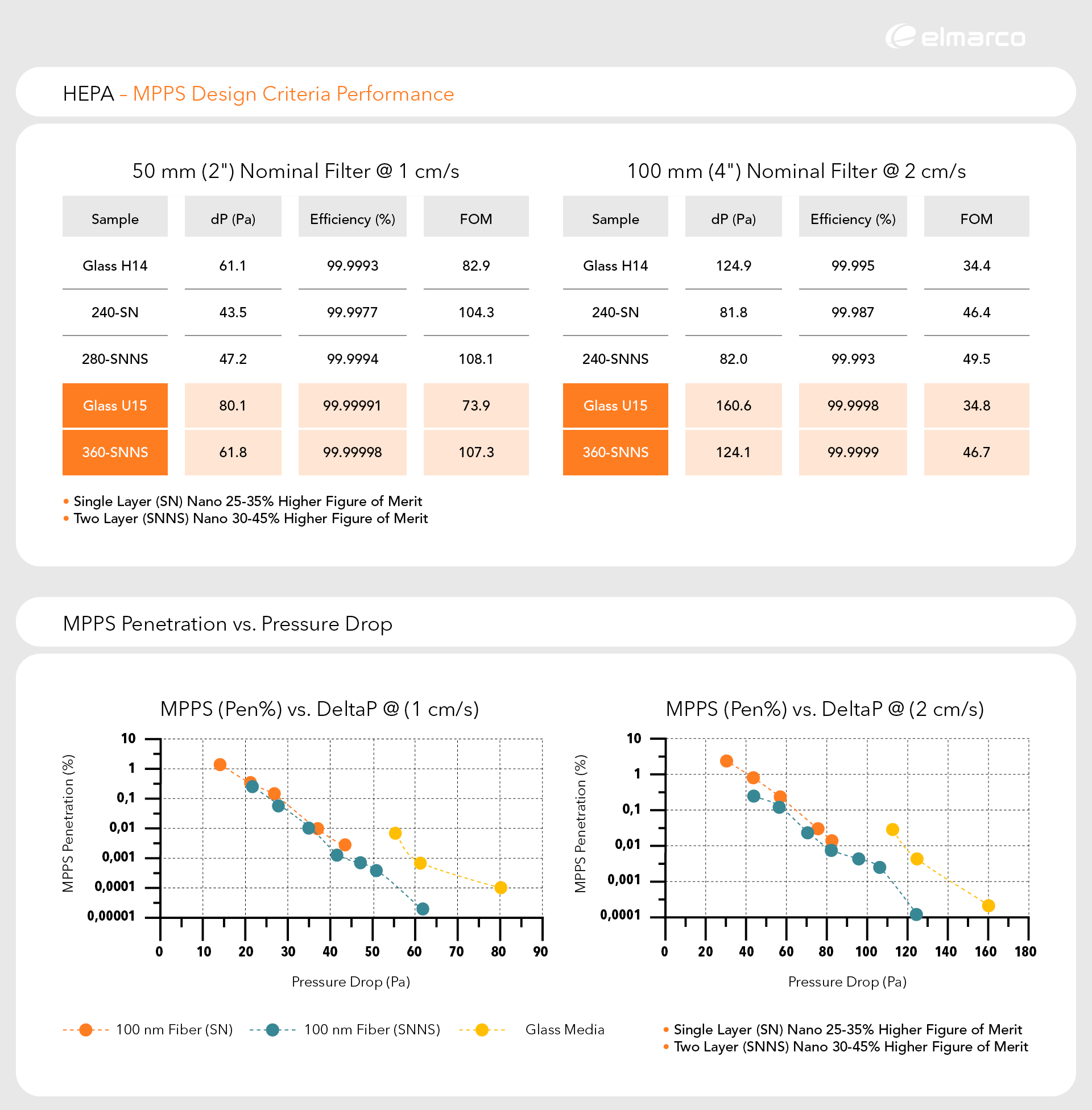

- Cleanroom (HEPA, ULPA)

Graph: HEPA – MPPS Design Criteria Performance a MPPS Penetration vs. Pressure Drop)

Graph: HEPA – MPPS Design Criteria Performance a MPPS Penetration vs. Pressure Drop)

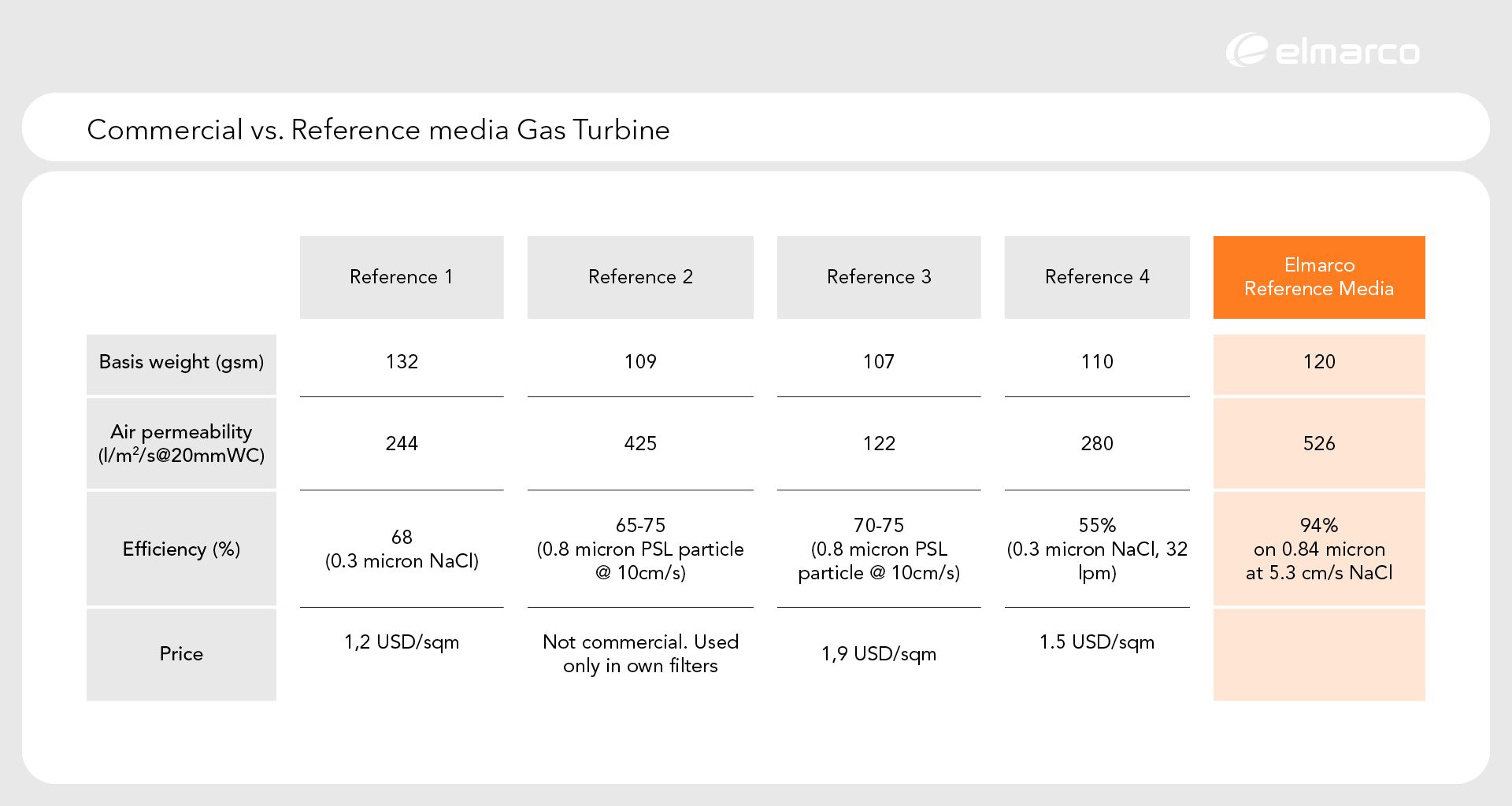

- Gas turbines filters

Graph: Commercial versus Reference media Gas Turbine

Graph: Commercial versus Reference media Gas Turbine

Nanofibers improve conventional air filters according to ISO 16890

ISO Coarse

Captures coarse debris (e.g. dust, sand or hair).

ISO ePM10

Captures particles smaller than 10 µm (e.g. bacteria, pollen grains, etc.). These can easily enter the upper respiratory tract.

ISO ePM2,5

Captures particles smaller than 2.5 µm. These can enter the lower respiratory tract. Suitable for nanofiber applications.

ISO ePM1

Captures particles smaller than 1 µm. These can enter the bloodstream. Suitable for nanofiber applications.

Nanospider™ gives materials unique properties

Submicron fiber diameter

- typical mean fiber diameter in the range from 75 nm to 250 nm

- even larger fiber diameters can be achieved

Large specific surface area and high porosity

- high porosity: 60‑90%

- relatively tight pore size distribution

- surface area 10–100 m²/g

Airflow efficiency and optimisation

- enables the production of high‑flow composite materials with excellent filtration efficiency

- mechanical filtration (not relying by electrostatic charge)

A wide range of materials

- a wide range of known polymer materials and their mixtures

- the possibility of incorporating additives into the fibers (e.g., silver for its antibacterial effects)

- integration with a wide range of substrate materials

Nanotechnology significantly improves your existing products

LINEA line

The LINEA line enables the production of nanofibers in large volume.

It is designed for ease of use, scalability, modularity and flexibility in producing the highest quality nanofibers for a wide range of air filters.

Contact us