Laboratory equipment for your own experimental work

NS LAB - available as part of your laboratory

State‑of-the‑art equipment for experimental work and product development

NS LAB is compact and affordable laboratory electrospinning equipment which allows for efficient nanofiber research, development of new nanofibrous products, and experimental nanomaterial work

- For Materials Science

- Technical textiles

- Membrane research

- Experimental research

NS LAB is a compact and affordable research tool. It is based on Nanospider™ technology, just like our industrial lines. This makes research done at the NS LAB easily transferable to an industrial scale.

NS LAB functions and recommended use

Designed to enable basic materials and application research. Various polymers can be used for electrospinning on the NS LAB equipment, thereby producing a wide range of synthetic, organic and biodegradable nanofibers.

Perfect for exploring

NS LAB is ideal for membrane research, air filtration, liquid filtration, medicine and many other applications.

Unique material

The material produced has high air permeability and uniformity compared to needle technologies.

Everything under control

Allows control of all process parameters (voltage, substrate speed, die size, application head speed, wire distance from the substrate, etc.)

Batch operation

Depending on the process settings, operating time ranges from 40 to 100 min with a single dose of 50 ml of solution. If needed, we also offer 10 ml and 100 ml containers.

Choose the right equipment for your research

NS LAB research kit

- NS LAB device

- Industrial camera set

-

Standard accessories

2x head for applying polymer solution, 4x sleeve, cleaning tube

- 1x substrate roll

- 2x complete two polymer production recipes

- 12-month warranty

- Online training

NS LAB research kit + air conditioning unit

- NS LAB device

- NS AC150 Air-conditioning unit

- Industrial camera set

-

Standard accessories

2x head for applying polymer solution, 4x sleeve, cleaning tube

- 1x substrate roll

- 2x complete two polymer production recipes

- 12-month warranty

- Online training

Do you need help choosing?

We will be happy to advise you which device is suitable for you

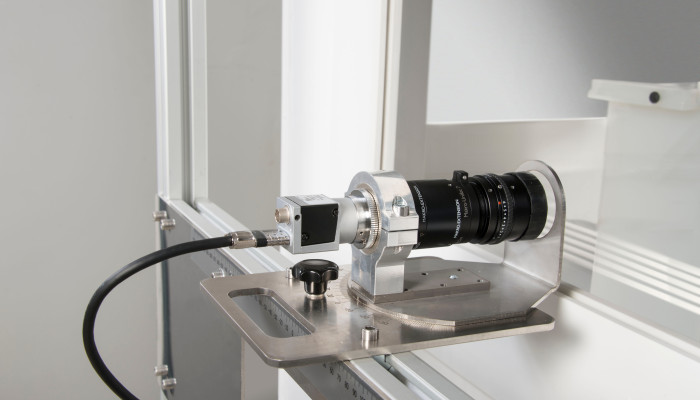

Non-binding inquiryNS LAB is equipped with an industrial camera

Industrial camera set offers a detailed view of the formation of nanofiber jets on a wire electrode. This enables quantitative image analysis of process specifications related to Nanospider™ technology. The camera can be used with shadow or reflection sensing methods.

Specifications that can be analyzed:

- Nanofibers formation

- Density of Taylor cones and their geometry

- Distance between individual jets

- Thickness and frequency of deposition of a thin layer of solution on a string electrode

Camera specificatons:

- Resolution 1 px = 12 μm and higher

- Exposure time 50 μs and higher

- Frame rate up to 500 frames/s (or 180 frames/s at full HD resolution)

NS LAB technical specifications

| Electrospinning unit | |

|---|---|

| Stationary wire system of electrodes | |

| Number of spinning electrodes | 1 |

| Spinning electrode width | 350 mm |

| Integrated one-way substrate material rewinding | |

| Electrospinning tension | 0‑80 kV |

| Unwinding speed | up to 5000 mm/min. |

| Electrode distance from the substrate | 120‑240 mm |

| Effective width of the nanofibrous layer | 250‑300 mm |

| Operating time with one dose of solution (50 ml) | 40‑100 min. |

| Consumption | |

| Power consumption | up to 300 W (without peripherals) |

| Dimensions | |

| Height | 2053 mm |

| Width | 1295 mm |

| Length | 1045 mm |

| Weight | 275 kg |

| Accessories | |

| Solution tank volume | 10, 50 and 100 ml |

| Tank cleaning container | |

| Optional Peripherals | |

| (NS AC 150) Air conditioning unit | |

| Industrial camera with adjustable stand | |

| Operating mode | Batch |

|---|---|

| Polymer batch volume | 50 ml or 10 ml |

| Process example for PA6 polymer | |

| Solution viscosity | 150 mPa*s |

| Average fiber diameter | 100 nm +/- 20 % |

| Weight of the nanofibrous layer | 2,8 g/m² |

| Effective width of the nanofibrous layer | 300 mm |

| Air permeability (at 200 Pa) | 11,5 l/m²/s +/- 7 % |

| Total run time per 50 ml dose | 100 min. |

| Polymer solution consumption | 0,5 g/min. |

| Spinning unit | |

|---|---|

| Operating staff 1 person | 1 person |

| Production premises 3×3 meters | 3×3 metres |

| Extraction ventilation connection required | |

| Appropriate exhaust air cleaning required | |

| Necessary fire extinguishing system connection | |

| External grounding is required | |

Optional peripherals for NS LAB

NS AC150 air conditioning unit

Air conditioning unit designed for Nanospider™ laboratory equipment and small‑volume production.

The NS AC150 unit supplies air with precise temperature and humidity levels to the NS LAB or NS 3S500U. Tightly controlling the temperature and humidity is critical to consistent and repeatable production of nanofiber materials.

Nominal process air flow: 150 m³/hour.

Technical parameters:

- Inlet temperature: 18,0–30,0 °C

- Inlet absolute humidity: 1.5-13.0 g/kg dry air

- Outlet temperature: 20.0-25.0 °C

- Output absolute humidity: 1.5-9.0 g/kg dry air

- Output temperature accuracy: +/- 1 °C

- Output humidity accuracy: +/- 3% RH

- External pressure: 200 Pa

- Under the conditions: p=1013 mbar and σ=1.2 kg/m³

* Under conditions: p=1013 mbar and σ=1.2 kg/m³

A chiller is an essential part of the equipment for the operation of the air conditioner. A chiller is a machine for the production of chilled water, which is used to extract the heat developed in various industrial processes.

Send us your non-binding inquiry