The New Horizon in Wound Care: Nanofiber Technologies for Accelerated Healing

The global wound care market is expected to soar to an unprecedented $27 billion by 2025, according to a report by Markets and Markets [1]. Amid this flourishing ecosystem, traditional methods of wound care are being overshadowed by burgeoning technologies. One such entrant promising to metamorphose this landscape is nanofiber technology [2]. This article sheds light on the revolutionary convergence between nanofibers and accelerated healing, a convergence that redefines the healing process itself.

The Limitations of Traditional Wound Care

Reports indicate that conventional wound care is set to see a decline in its growth rate, hovering at a Compound Annual Growth Rate (CAGR) of only 7.5 % by 2031 [3]. While gauze, bandages, and antiseptics have been the linchpin of wound care, they are no longer sufficient in a world that craves rapid and effective healing solutions.

The Power of Nanofibers in Wound Healing?

- Infection Control: Traditional methods often fall short in preventing bacterial infections, leading to complicated healing processes.

- Healing Speed: Slow rates of healing subject patients to prolonged periods of discomfort and potential complications.

- Bacterial Resistance: Conventional methods often lack robust mechanisms to combat bacterial infections, leading to complications and extended healing durations.

- Economic Considerations: The longer healing process and potential for complications result in escalated healthcare expenses, creating a demand for more cost‑effective alternatives.

Introduction to Nanofibers

In a world where superheroes are celebrated, nanofibers are the unsung heroes in the microscopic realm. These fibres, with diameters less than 100 nanometres, offer an immense surface area that can be custom‑tailored for specific medical applications [4]. They are not merely scientific novelties but game changers in the realm of wound care.

The Convergence of Nanofibers and Traditional Wound Care

Why settle for mediocrity when excellence is within reach? Nanofibers are breaking the barriers of traditional wound care. Melding nanofibers with existing wound care practices is not just innovative; it's revolutionary. Electrospun nanofibers have a large specific surface, high porosity, good mechanical properties, and excellent biocompatibility, which are beneficial to wound moisturizing, cell growth and respiration, and skin regeneration [5,6]. Nano‑based treatments for wound healing are showing great promise. Besides traditional commercial products, we can speed up the healing process and lower the chance of getting an infection.

Remarkable Benefits:

- Enhanced Drug Delivery: Nanofibers can encapsulate antibiotics or other medical agents and deliver them directly to the wound site. According to the Journal of Materials Science: Materials in Medicine, a 40% increase in drug penetration was achieved in wounds treated with nanofiber dressings [7]. Bakhsheshi‑Rad et al. developed gentamycin‑loaded chitosan‑alginate fibres for wound healing. The prepared mats displayed good antibacterial activity, cell attachment, and in vitro proliferation with enhanced regeneration of mice skin. In another study, moxifloxacin‑loaded chitosan/PEO nanofibers were fabricated to provide enhanced healing and antibacterial efficacy as a wound dressing [8].

- Extended Longevity: The process of skin wound repair is intricate and can be compromised by ongoing bacterial contamination and sustained inflammatory responses. Research indicates that nanofiber dressings can be effective for a longer period, reducing the frequency of dressing changes. In a composite material of PLA/CA/PEO, a sulphonamide analogue was incorporated as the active agent, using a DCM/DMF solvent system to create a blend. This composite exhibited both antibacterial and anti‑inflammatory properties [9]. In a blended composite material consisting of either PCL/PLLA or PCL/PDLG, Arrabidaea chica extract was integrated as the bioactive component. Utilizing a solvent system of chloroform and methanol, the resulting composite displayed anti‑inflammatory properties [10].

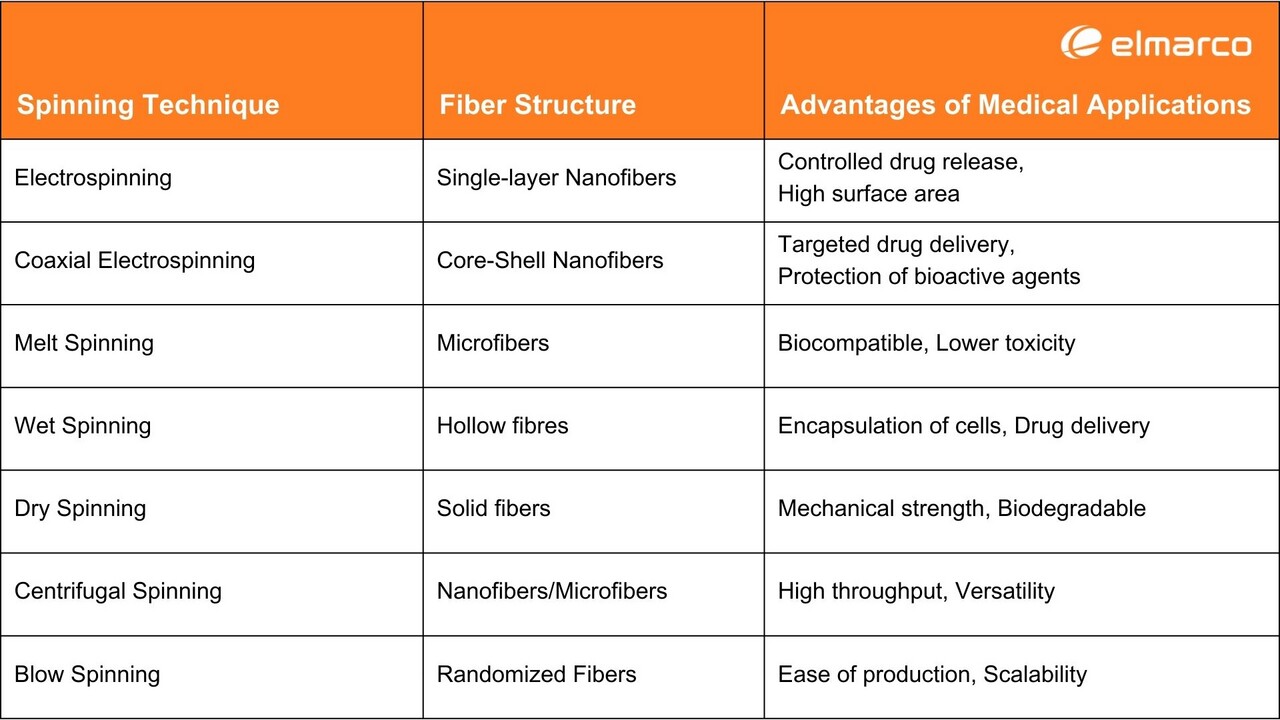

- Precision Healing: The unique architecture of nanofibers, which can be obtained by different methods, enables targeted delivery of drugs, making them highly effective in the treatment of complex wounds. Table 1 provides the advantages of different spinning techniques in the medical field.

Table 1: Comparison of Various Spinning Techniques, Their Resulting Fiber Structures, and Advantages for Medical Applications [11].

- Biocompatibility: Nanofibers are often made from biocompatible materials, reducing the risk of allergic reactions and side effects. Jiang et al. developed a composite scaffold using electrospun PCL/gelatin fibres, enhancing both surface wettability and cell‑binding sites compared to pure PCL scaffolds. Tests showed that mesenchymal stem cells interacted more favourably with the PCL/gelatin scaffolds, indicating potential applications in vascular tissue engineering [12]. Pezeshki‑Modaress et al. created gelatin/GAG nanofibrous mats through electrospinning, using 50% water in a TFE solvent system for optimal solubility. Fibre diameter was affected by the applied voltage and flow rate, with the best conditions identified for minimal mean fibre diameter and distribution. These mats show promise as scaffolds for skin, cartilage, and cornea tissue engineering [13].

- Eco‑Friendly: Many nanofibers are biodegradable, aligning with the growing demand for sustainable medical products. Park et al. created an electrospun chitosan‑cellulose composite mesh with effective antibacterial properties, suitable for treating skin ulcers either as a standalone bandage or integrated into other absorbents [14]. Miao et al. used electrospinning to fabricate fibres from cellulose and its composites with PMMA and chitosan, aiming for use in anti‑infective bandages [15].

The Future of Wound Care with Nanofibers

Envision a near‑future where your wound dressing is not just a passive barrier but an intuitive, self‑adjusting healer. From dressings that auto‑dispense antibiotics upon sensing bacterial activity to those that change colours according to the healing stage, nanofibers are set to transform wound care from a routine medical procedure into a dynamic, interactive experience. This isn't a mere upgrade; it's a groundbreaking revolution that promises to make traditional wound care methods obsolete, heralding an era where healing is faster, smarter, and more efficient than ever before.

Conclusions

As we stand on the cusp of a new era in healthcare, nanofibers are emerging as the vanguard of a revolution that is poised to redefine wound care from its very foundations. This isn't a fleeting trend or a minor upgrade; it's a seismic metamorphosis fuelled by cutting‑edge science, offering transformative benefits that extend from individual patients to global healthcare systems. Nanofibers are doing more than just accelerating the healing process; they're amplifying its efficiency, reducing risks, and promising a future where wound care is not just quicker but also more intelligent and sustainable. In an age where time is of the essence, these microscopic dynamos are orchestrating a new rhythm in healing, setting the stage for a future where advanced wound care will be the norm, not the exception. This revolution is not just reshaping our approach to wound care; it's setting a new gold standard that harmonizes patient well‑being with planetary health.

Abbreviations

CAGR: Compound Annual Growth Rate

PCL: Polycaprolactone

PEO: Polyethylene Oxide

PLLA: Poly(L‑lactic acid)

PDLG: Poly(D,L‑lactide-co‑glycolide)

GAG: Glycosaminoglycan

TFE: Trifluoroethanol

PLA: Polylactic Acid

CA: Cellulose Acetate

DCM: Dichloromethane

DMF: Dimethylformamide

References

[1] Wound Care Market Revenue Trends and Growth Drivers. MarketsandMarkets n.d. https://www.marketsandmarkets.com/Market‑Reports/wound‑care-market‑371.html (accessed September 8, 2023).

[2] Ataide JA, Zanchetta B, Santos ÉM, Fava ALM, Alves TFR, Cefali LC, et al. Nanotechnology‑Based Dressings for Wound Management. Pharmaceuticals (Basel) 2022;15:1286. https://doi.org/10.3390/ph15101286.

[3] Bioactive Wound Care Market to Exhibit 7.5% CAGR by 2031, Transforming Wound Healing Approaches Globally. MarketWatch n.d. https://www.marketwatch.com/press‑release/bioactive‑wound-care‑market-to‑exhibit-7‑5-cagr‑by-2031‑transforming-wound‑healing-approaches‑globally-acbbda9a (accessed September 8, 2023).

[4] Bartels VT. Handbook of Medical Textiles. 2011.

[5] Laezza A, Pepe A, Henry A, Duca L, Bochicchio B. Polysaccharide‑Enriched Electrospun Nanofibers for Salicylic Acid Controlled Release. ACS Appl Eng Mater 2023;1:508–18. https://doi.org/10.1021/acsaenm.2c00119.

[6] Khan M, Kharaghani D, Kim I‑S, Khatri Z. Nanofibers for Medical Textiles, 2018, p. 1–17. https://doi.org/10.1007/978‑3-319‑42789-8_57‑1.

[7] Duan X, Chen H, Guo C. Polymeric Nanofibers for Drug Delivery Applications: A Recent Review. J Mater Sci Mater Med 2022;33:78. https://doi.org/10.1007/s10856‑022-06700‑4.

[8] Bakhsheshi‑Rad HR, Hadisi Z, Ismail AF, Aziz M, Akbari M, Berto F, et al. In vitro and in vivo evaluation of chitosan‑alginate/gentamicin wound dressing nanofibrous with high antibacterial performance. Polymer Testing 2020;82:106298. https://doi.org/10.1016/j.polymertesting.2019.106298.

[9] Chen K, Hu H, Zeng Y, Pan H, Wang S, Zhang Y, et al. Recent advances in electrospun nanofibers for wound dressing. European Polymer Journal 2022;178:111490. https://doi.org/10.1016/j.eurpolymj.2022.111490.

[10] Lima LL, Taketa TB, Beppu MM, Sousa IM de O, Foglio MA, Moraes ÂM. Coated electrospun bioactive wound dressings: Mechanical properties and ability to control lesion microenvironment. Materials Science and Engineering: C 2019;100:493–504. https://doi.org/10.1016/j.msec.2019.03.005.

[11] Barhoum A, Bechelany M, Hamdy Makhlouf AS. Handbook of Nanofibers. 2019. https://doi.org/10.1007/978‑3-319‑53655-2.

[12] Jiang Y‑C, Jiang L, Huang A, Wang X‑F, Li Q, Turng L‑S. Electrospun polycaprolactone/gelatin composites with enhanced cell‑matrix interactions as blood vessel endothelial layer scaffolds. Mater Sci Eng C Mater Biol Appl 2017;71:901–8. https://doi.org/10.1016/j.msec.2016.10.083.

[13] Pezeshki‑Modaress M, Mirzadeh H, Zandi M. Gelatin–GAG electrospun nanofibrous scaffold for skin tissue engineering: Fabrication and modeling of process parameters. Materials Science and Engineering: C 2015;48:704–12. https://doi.org/10.1016/j.msec.2014.12.023.

[14] Park T‑J, Jung YJ, Choi S‑W, Park H, Kim H, Kim E, et al. Native chitosan/cellulose composite fibers from an ionic liquid via electrospinning. Macromol Res 2011;19:213–5. https://doi.org/10.1007/s13233‑011-0315‑0.

[15] Miao J, Pangule RC, Paskaleva EE, Hwang EE, Kane RS, Linhardt RJ, et al. Lysostaphin‑functionalized cellulose fibers with antistaphylococcal activity for wound healing applications. Biomaterials 2011;32:9557–67. https://doi.org/10.1016/j.biomaterials.2011.08.080.