How are Sustainable Electrospun Polymers Enabling a Green Revolution?

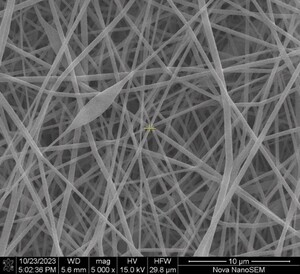

The escalating global concerns over plastic waste, air and water pollution have catalyzed the search for sustainable solutions. Among these, electrospun nanofibers have emerged as a promising solution, particularly in water treatment applications.1 Significant advancements in electrospinning methodologies have propelled the production of nanofiber materials into mainstream usage, marking a vital transition from niche applications to industrial‑scale production.2

Electrospun polymers demonstrate unparalleled characteristics, making them ideal candidates for filters. Their high degree of tunability in terms of porosity, remarkable surface‑to-volume ratios, and excellent pore connectivity render them efficient filtration materials.3 Many electrospun polymers also have excellent biodegradability and recyclability, and fibers can also be functionalized with other species, such as nanoparticles, to imbue additional material properties, such as antibacterial functionality.

Electrospinning is inherently well‑suited to nanofiber creation and has the potential to aid in both the production of large‑area fiber material and tackle one of the biggest challenges facing all industrial manufacturing sectors – sustainability and waste reduction.

Electrospinning is inherently well‑suited to nanofiber creation and has the potential to aid in both the production of large‑area fiber material and tackle one of the biggest challenges facing all industrial manufacturing sectors – sustainability and waste reduction.

While polymer nanofibers have many desirable properties, many sustainability issues surrounding plastic waste also apply to nanofibers. Traditional polymers are typically sourced from feedstocks derived from oil and fossil fuels, and their poor biodegradability, with decomposition times of 20–500 on average, are all adding to growing landfill problems.2 However, with these concerns in mind, the industry is now shifting towards greener polymer sources, promoting recycling and embracing circular economy principles.4 Such polymers are derived from renewable feedstocks, such as plant materials, and are typically more suitable for recycling.

In addition to concerns related to polymer materials, electrospinning manufacturing poses sustainability challenges due to the utilization of solvents, many of which contribute to environmental and pollution issues. Hence, exploring the current state‑of-the‑art regarding electrospinning with environmentally friendly solvents is crucial.

This article will delve into the sustainability of electrospun polymers, analyzing environmentally friendly alternatives and addressing the challenges that remain to create a greener future.

Electrospinning – Solvents, Polymers and Substrates

In the realm of electrospinning, the shift toward sustainable practices hinges on two key factors: the use of biodegradable polymer bases and the integration of eco‑friendly solvents. Notably, green solvents offer immense potential for various electrospinning methods, including needle and needleless techniques, yielding comparable results without relying on toxic substances or those derived from petroleum chemistry.7 Yet, despite their potential, there are still certain barriers to the widespread adoption of green solvents.

The adoption of green solvents, while promising, presents challenges due to their sensitivity to environmental conditions, leading to complexities in their utilization. A significant obstacle to their widespread adoption lies in the need for further process optimization and the scarcity of general procedures. Nevertheless, advancements in synthetic routes utilizing green solvents have yielded nanofibers with desirable traits such as air permeability, repellency, and enhanced filtration capabilities.7 Moreover, many green solvents can be seamlessly integrated with advanced electrospinning techniques, facilitating the creation of functionalized nanofibers.

When seeking more environmentally friendly starting materials for electrospun polymers, two primary options come into play: biopolymers (derived entirely from biological resources) or bio‑sourced/biobased materials (comprising a certain proportion of biopolymer). However, how well a specific polymer/solvent combination spins depends on the types of solvent‑polymer interaction.

In this context, solubility emerges as a critical factor in identifying compatible pairs, as the solvent must effectively dissolve the polymer starting materials. Various fluid properties, including viscosity, surface tension, elasticity, and conductivity, significantly influence the ultimate properties of the fibers. For instance, when the Taylor cone is formed during the electrospinning process, it is the Rayleigh instability that determines when capillary breakup occurs. To avoid unwanted breakup, it is important to find combinations of solvents with the right surface tension to match the viscoelasticity of the polymer fibers that are also related to the polymer concentration being used.

Moreover, the market is witnessing a rising trend toward the development of novel substrate materials sourced from bio‑based or green starting materials. These efforts aim to enhance the biodegradability and recyclability of nanofiber‑coated materials, aligning with the growing demand for eco‑friendly solutions.

Sustainable Biobased Polymers

In the realm of nanofiber electrospinning, numerous green polymers are currently being utilized, each with its unique applications and the added benefits they gain from the electrospinning process.

Polyester Derivative (PETG): This cost‑effective polymer offers an eco‑friendly alternative to PET and eliminates the need for processing with fluorinated solvents. PETG’s versatility allows it to be functionalized, meaning that it is ideal for various applications. Moreover, it can be spun into thinner structures than traditional PET, making it well‑suited for 3D printing with enhanced thermal properties and packaging applications.

Polylactic Acid (PLA) and Polycaprolactone (PCL): Polylactic acid and polycaprolactone are exceptional biobased polymers. Microbial polymerization can even be used to help drive the process, adding to their sustainable appeal. Both PLA and PCL are highly compostable, with PLA being particularly biocompatible for numerous biomedical applications.

Polylactic Acid (PLA) and Polycaprolactone (PCL): Polylactic acid and polycaprolactone are exceptional biobased polymers. Microbial polymerization can even be used to help drive the process, adding to their sustainable appeal. Both PLA and PCL are highly compostable, with PLA being particularly biocompatible for numerous biomedical applications.

TPU/Polyamides: These polymers boast excellent strength and chemical resistance, making them well‑suited for bioapplications, particularly in the realm of wound compatibility. Electrospinning enables the creation of very small fiber dimensions, and these polymers exhibit high solubility.

Cellulose: Revered as one of the world’s most advanced biomass materials, cellulose is extremely environmentally compatible and boasts excellent biodegradability. As a filter material, it excels in packaging applications. Cellulose can also be electrospun into ultrafine fibers as small as 300 nm, possessing low thermal expansion while remaining lightweight yet strong.2,3

Chitosan: Chitosan is a bio‑based polymer with excellent water uptake properties and is used to form hydrogels. Bioactive compounds can also be incorporated, making them ideal for use in medical compounds and wound treatment.4

The integration of these sustainable biobased polymers into the nanofiber electrospinning process not only expands their range of applications but also contributes significantly to the pursuit of environmentally friendly solutions in various industries.

Low Energy Solution For Waste Air Treatment

The environmental and economic consequences associated with waste air from chemical processing represent substantial challenges in today’s industrial landscape. This waste air typically carries elevated levels of particulate matter, raising serious concerns about its impact. Regardless of the type of solvent used, the methods employed for waste air treatment are relatively consistent and include catalytic systems, thermal systems, and scrubbers. Among these, scrubbers are the most prevalent choice for treating contaminated wastewater. However, emerging technologies like low‑temperature plasmas offer a promising alternative, providing more efficient waste air treatment with reduced energy demands.8

Green solvents can help to eliminate costly particle recycling or trapping systems, as there is no longer a need for waste air treatment as harmful solvents are no longer used as part of the manufacturing process.8,10 However, where the use of green solvents is not possible, different solutions to recycling waste air must be found. Every stage of the electrospinning process, from creating solutions and polymers to preparing substrates, generates waste air. Thus, focusing recycling efforts on this waste air presents a valuable opportunity to bolster the industry’s sustainability efforts.

Catalytic and thermal scrubbers operate by absorbing unwanted pollutants onto the surface of the material. Then, the VOC can either be trapped, where it can later be removed by some form of rinsing process, or undergo some kind of degradation reaction or thermal decomposition to form other benign chemical products. One problem with this, however, is that the reaction conditions often necessitate extremely high temperatures, resulting in significant energy consumption during the desorption and cleaning stages.

Alternatively, scrubber systems typically use a chemical trap, like an activated carbon that adsorbs VOCs onto its surface to trap them. Wet scrubbers use a spraying system to spray incoming waste air with a liquid, usually water, to help remove any dust and particulate matter. Sometimes, other chemical species are added that either react and break down any VOCs present or help trap species.

Low‑temperature plasmas, on the other hand, offer a more energy‑efficient approach to waste cleanup. In plasma cleanup, reactive radical species are formed, which subsequently react with unwanted pollutants, leading to their degradation. The high efficiency of low‑temperature plasmas positions them as an ideal, energy‑saving alternative to scrubbers, contributing to the overall sustainability of nanofiber production.

Scaling Up

Nanofiber production using green polymers and green solvents has achieved remarkable scalability in recent years. However, there are specific challenges associated with scaling up, mainly to do with the volumes of solvents required for processing, which, in turn, further emphasizes the need for process optimization. This comes from gaps in the fundamental understanding of how the electrospinning process works for fibers on the nanoscale, making it difficult to predict the types of interactions between a solute/solvent pair.

However, collaborating with electrospinning experts like Elmarco can be highly beneficial. Elmarco can help reduce the costly burden of research and development for creating or adapting a new electrospinning process for new solvents or starting materials. Our extensive expertise in electrospinning processing can provide invaluable support and guidance, streamlining the journey toward innovative and efficient solutions.

To learn more and explore further possibilities, get in touch with us today.

References and Further Reading:

- Feng, C., Khulbe, K. C., Matsuura, T., Tabe, S., & Ismail, A. F. (2013). Preparation and characterization of electro‑spun nanofiber membranes and their possible application in water treatment. Separation and Purification Technology, 102, 118–135. https://doi.org/10.1016/j.seppur.2012.09.037

- Elmarco (2023) Sustainability in Electrospinning, https://youtu.be/B2LlG8kI9p8, accessed July 2023

- Zhang Y, Zhang C, Wang Y. Recent progress in cellulose‑based electrospun nanofibers as multifunctional materials. Nanoscale Adv. 2021;3(21):6040‑6047. doi:10.1039/d1na00508a

- Celebioglu A, Saporito AF, Uyar T. Green Electrospinning of Chitosan/Pectin Nanofibrous Films by the Incorporation of Cyclodextrin/Curcumin Inclusion Complexes: pH‑Responsive Release and Hydrogel Features. ACS Sustain Chem Eng. 2022;10(14):4758‑4769. doi:10.1021/acssuschemeng.2c00650

- Zhou, Y., Liu, Y., Zhang, M., Feng, Z., Yu, D. G., & Wang, K. (2022). Electrospun Nanofiber Membranes for Air Filtration: A Review. Nanomaterials, 12(7). https://doi.org/10.3390/nano12071077

- Syberg, K., Nielsen, M. B., Westergaard Clausen, L. P., van Calster, G., van Wezel, A., Rochman, C., Koelmans, A. A., Cronin, R., Pahl, S., & Hansen, S. F. (2021). Regulation of plastic from a circular economy perspective. Current Opinion in Green and Sustainable Chemistry, 29, 100462. https://doi.org/10.1016/j.cogsc.2021.100462

- Mosher, C. Z., Brudnicki, P. A. P., Gong, Z., Childs, H. R., Lee, W., Antrobus, R. M., Fang, E. C., Schiros, T. N., & Lu, H. H. (2022). Green electrospinning for biomaterials and biofabrication. Biofabrication, 13(3), 035049. https://doi.org/10.1088/1758‑5090/ac0964.Greens

- Avossa, J., Herwig, G., Rossi, R. M., & Toncelli, C. (2022). Electrospinning based on benign solvents: current definitions, implications and strategies. Green Chemistry, 24, 2347–2375. https://doi.org/10.1039/d1gc04252a

- Kurecic, Mohan, T., Virant, N., Maver, U., Stergar, K., Gadinsknik, K., Kleinschek, K. S., & Hribernik, S. (2019). A green approach to obtain stable and hydrophilic cellulose‑based electrospun nanofibrous substrates for sustained release of therapeutic molecules. RSC Advances, 0, 21288–21301. https://doi.org/10.1039/c9ra03399h

- Zhang, X., Ru, Z., Sun, Y., Zhang, M., Wang, J., Ge, M., Liu, H., Wu, S., Cao, C., & Ren, X. (2022). Recent advances in applications for air pollutants purification and perspectives of electrospun nanofibers. Journal of Cleaner Production, 378, 134567. https://doi.org/10.1016/j.jclepro.2022.134567